Professional. Passionate. Persevering.

The company was founded in November 2005,located in Wenling,Zhejiang Province,China. The company is a high-tech enterprise ,which is committed to the research and development of exhaust gas after-treatment technologies.Our products range from metal honeycomb carriers,catalytic materials,catalyst for motorcycle,gasoline/diesel engine, catalytic converters and EGR cooler. Under the backgound of pollution and carbon reduction ,OXIN wants to make a change for the environment.

We have a strong R&D team,and we can develop and produce products according to the drawings or samples the customers offered.

Development and production of exhaust gas treatment catalysts for various fuel types to meet the requirements of different car models, different emissions and different requirements.

With an annual production capacity of over 10 million liters, we can meet the needs of customers with different purchasing volumes.

LNG: Liquefied Natural Gas CNG: High Pressure Natural Gas Comparison of ignition points. Diesel fuel: ignition point 220℃; gasoline ignition point 427℃. But gasoline is volatile, gasoline vapor to diesel fuel ignition point is low. Liquefied Petroleum Gas (LPG):ignition point 490℃. Natural gas: ignition point 650 ℃. Gas: gas mixture, ignition point greater than 50...

The engine exhaust temperature is 100℃-150℃ higher than that of diesel engine, which requires higher oxidation resistance and anti-nitrification of engine oil; high heat load requires that the viscosity of engine oil movement should not be too high to ensure good cooling performance. The sulfur content of natural gas is lower than the sulfur content in diesel oil, requiring the oil to have lo...

So far, most humans use flame combustion, but scientific research shows that the traditional flame combustion method has low thermal efficiency and heavy pollution, which restricts the development of our economy. The fundamental way to solve the inefficiency and high emission of flame combustion is catalytic combustion. In this study, based on the progress made in rare earth oxygen storage materia...

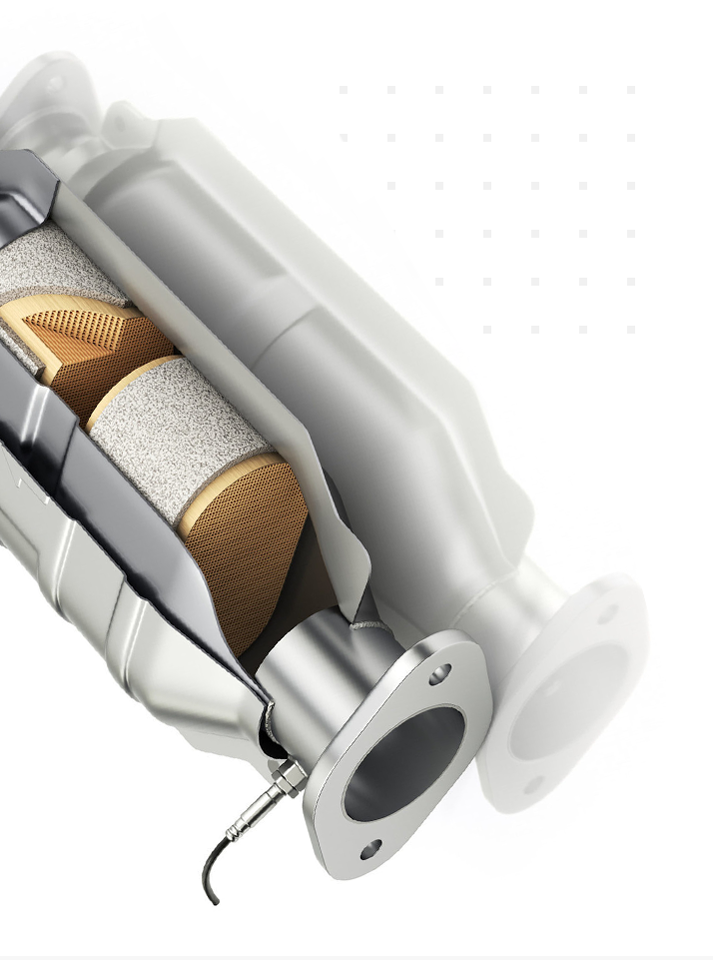

Metal honeycomb carrier has the advantages of fast ignition, small volume, high strength and good heat resistance, which is widely used in motorcycle exhaust gas purification. It is made by pretreating the surface of metal honeycomb carrier and generating a transition layer between metal honeycomb carrier and active coating to solve the thermal expansion matching gradient transition between metal ...

At present, EFI vehicles are already very common, and the cars updated after 1999 in Beijing, including cabs, are basically electronically controlled gasoline injection and equipped with three-way catalytic converters. As the price of the three-way catalytic converter is not expensive, so the reasonable use of the three-way catalytic converter to extend the life of the majority of drivers, includi...

+86-0576-86169628

+86-0576-86169628

+86-13989635917

+86-13989635917

+86-0576-86165339

+86-0576-86165339

huangying@oxinhuanbao.com

huangying@oxinhuanbao.com

No.6,24th Street,East New District, Wenling,Taizhou,Zhejiang,China

No.6,24th Street,East New District, Wenling,Taizhou,Zhejiang,China